-

Solution for Data Acquisition, Remote Monitoring, and Control System of Pultrusion Machines

2025-08-27 17:53:32

A pultrusion machine is a processing equipment used for manufacturing composite materials.

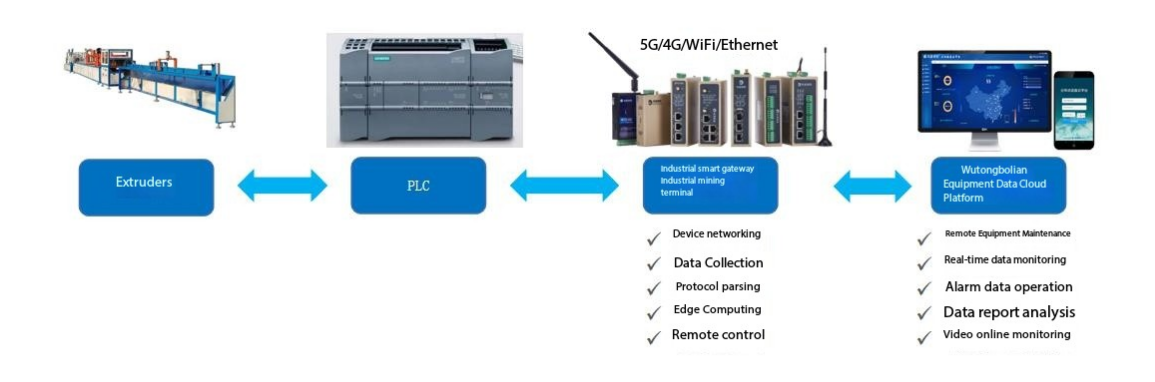

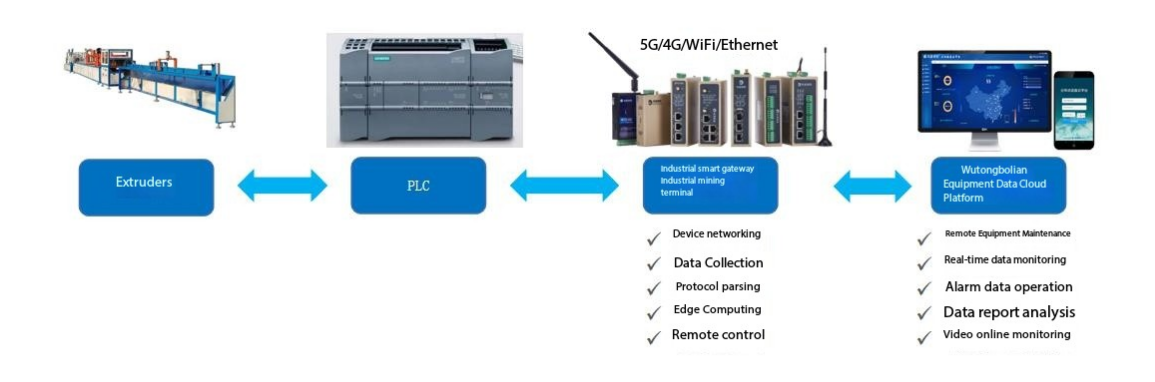

It utilizes a polymer matrix to extrude reinforcing materials (fibers or fabrics) as a continuous phase through an extruder, which are then shaped into composite materials using a molding die. The main advantages of the pultrusion process include the ability to produce thicker products with smooth surfaces, while also controlling material rheological behavior and product strength. Its products are widely applicable in various fields such as electrical engineering, anti-corrosion engineering, construction industry, and transportation.By integrating the PLC of a pultrusion machine with the Wutongbolian industrial intelligent gateway, the gateway can perform protocol parsing and data acquisition.

It uploads data such as pressure, temperature, and pultrusion speed to a cloud platform or upper computer via 5G/4G/WIFI/Ethernet, enabling real-time monitoring and visual management of the process flow. It can also automatically issue alarms for equipment faults or abnormal conditions, utilizing remote control and remote maintenance to swiftly address issues and maintain a safe and stable production environment.

System Functionalities

-

Real-time Monitoring: The system monitors the operational status of the pultrusion machine in real-time, including parameters such as temperature, pressure, and speed.

-

Automatic Alarming: When abnormal operating conditions occur, the system automatically triggers alarms to remind personnel to take timely measures.

Alerts can be sent via WeChat, SMS, email, etc. -

Data Analysis: The system can analyze the operational status of the pultrusion machine, such as energy consumption and production output, to optimize the production process and enhance efficiency.

-

Remote Monitoring: The system enables remote monitoring of the pultrusion machine's operational status via the internet on mobile or computer terminals, allowing managers to stay informed about production conditions.

-

Remote Control and Maintenance: The system supports remote starting/stopping of PLCs, remote programming and debugging, and remote program uploading/downloading for异地 (off-site) equipment, improving maintenance efficiency.

-

Go Top

Go Top