-

Solution for Remote Monitoring and Fault Alarm System of Sand Making Machines

2025-08-27 17:51:40

A sand making machine is a mechanical device used for producing sand of varying strengths.

It combines processes such as stone crushing and screening to produce sand that meets specific requirements, widely applied in construction, highway, railway, water conservancy, and other fields. It serves as a primary production equipment for industrial sand, including construction sand and cement sand.The main components of an automated sand making machine include crushers, vibrating screens, feeders, controllers, etc.

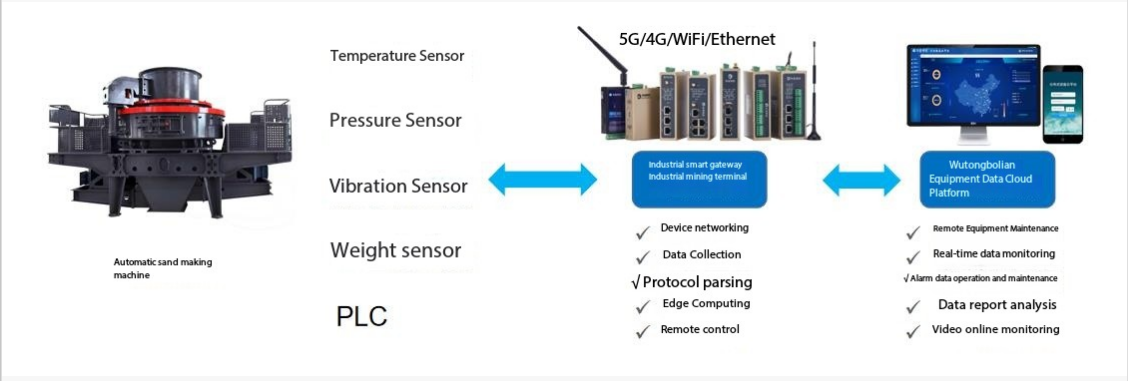

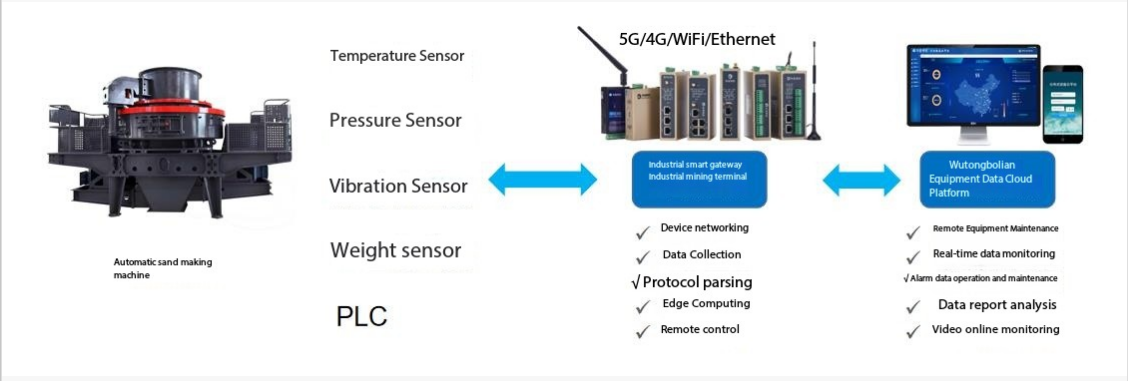

Its working principle involves using a crusher to break down stones, followed by a vibrating screen to separate and classify the stones into different sizes of sand. During the sand production process, data such as temperature, pressure, vibration, weight, voltage, and current are crucial for efficient and stable production. It is essential to collect and monitor this data in real-time to achieve refined production management and reduce material losses and energy consumption costs.By integrating the Wutongbolian industrial intelligent gateway into the PLC and sensors of a sand making machine, the gateway performs automated protocol parsing and data collection.

It uploads data such as temperature, pressure, vibration, weight, voltage, and current to a cloud platform or upper computer, enabling functions such as equipment operation monitoring, fault alarms, remote control, and remote maintenance. This effectively enhances work efficiency and management standards while improving production efficiency and sand quality.

Functional Characteristics

-

Enhanced Production Efficiency: The system enables real-time monitoring of the sand making machine.

In case of a fault, the system promptly issues an alarm, prompting maintenance personnel to take action, thereby improving production efficiency. -

Reduced Maintenance Costs: The system can detect issues before they lead to failures and provides remote program uploading/downloading and remote debugging capabilities, minimizing equipment downtime and reducing maintenance costs.

-

Improved Equipment Operational Stability: The system conducts real-time monitoring and analysis of the sand making machine's operational data, providing visual data charts.

This enables timely measures to be taken to ensure equipment stability and reliability. -

Enhanced Safety: The system promptly detects equipment faults and notifies relevant personnel via WeChat, SMS, email, etc., reducing the occurrence of equipment accidents and enhancing production safety.

-

Go Top

Go Top