-

Solution for Data Acquisition and Remote Monitoring of Oxidation Wastewater Treatment Equipment

2025-08-27 17:55:24

Oxidation wastewater treatment equipment is utilized for treating wastewater, primarily aimed at converting organic pollutants into harmless substances to reduce environmental pollution and resource waste.

This equipment typically employs biomembrane reactor technology, where organic pollutants are adsorbed, degraded, and transformed by microorganisms on the biomembrane, achieving the purpose of water purification. After operations such as chemical dosing and mixing, the wastewater enters the biomembrane reactor and interacts with microorganisms on the biomembrane, converting organic pollutants into harmless substances like carbon dioxide, water, and inorganic salts.Oxidation wastewater treatment equipment is widely applied in urban wastewater treatment, industrial wastewater treatment, and other fields, effectively reducing wastewater discharge and protecting the environment and human health.

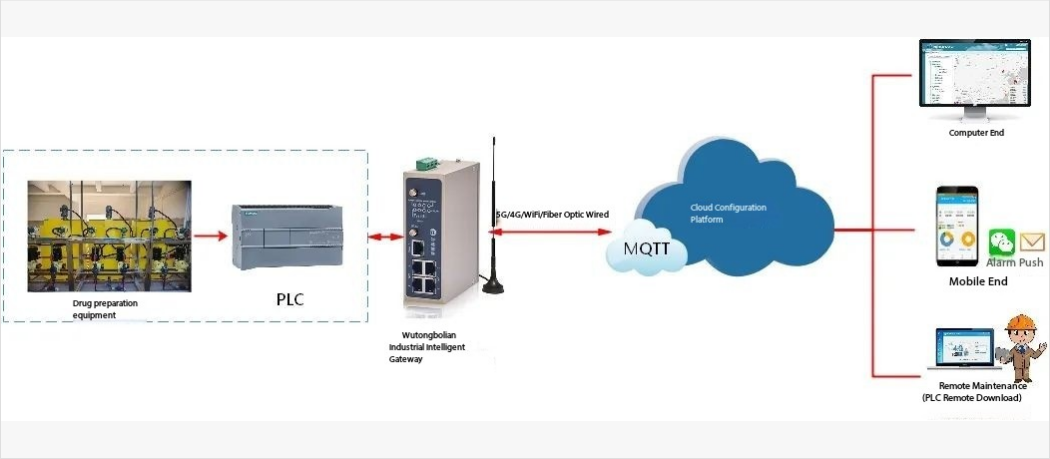

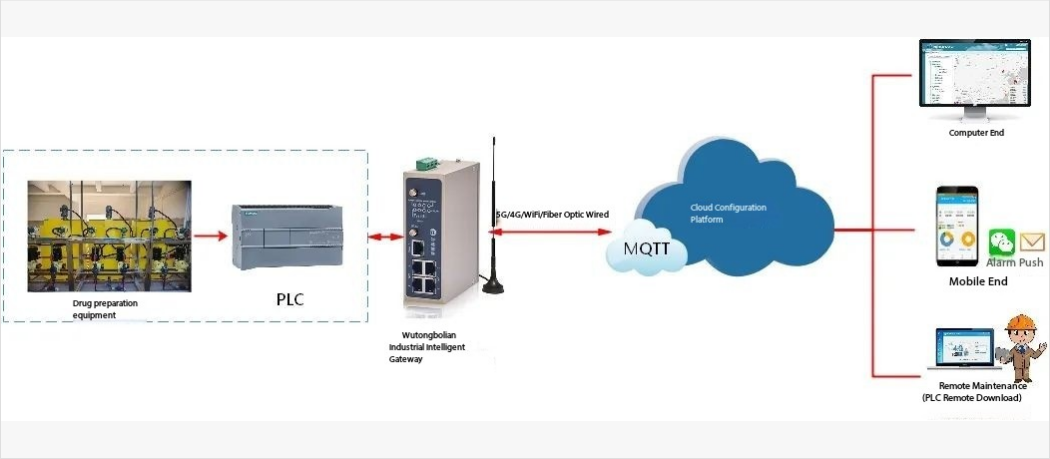

Simultaneously, this equipment offers advantages such as energy conservation, environmental protection, and cost-effectiveness, making it a crucial tool in modern wastewater treatment.To ensure the safe and stable operation of the equipment, many wastewater treatment plants demand data acquisition and monitoring of the wastewater treatment equipment, along with fault预警预报 (early warning and prediction), production data analysis, and remote control and maintenance of the equipment. By integrating the Wutongbolian industrial intelligent gateway into the PLC and sensors of the oxidation wastewater treatment equipment, real-time data collection of parameters such as temperature, pressure, water level, vibration, flow rate, and water quality can be achieved, along with real-time monitoring of equipment switch status.

Intelligent alarm rules can be set to automatically trigger alarms for abnormal fault conditions, and remote control and maintenance tools can be employed for swift management and control. This effectively helps enterprises stay informed about equipment status and manage it in a timely manner, ensuring efficient and smooth wastewater treatment processes and compliant water quality standards.

System Functionalities

-

Support for Configuration Monitoring: The system supports configuration monitoring of processes such as water intake, drainage, chemical dosing, filtration, decontamination, and advanced treatment. It enables remote monitoring of equipment operational status and water quality parameters (flow rate, pressure, liquid level, water quality, temperature, etc.), along with real-time visualization and processing of the data.

-

Intelligent Data Analysis: The system performs intelligent analysis on historical and real-time data of the entire system (energy consumption data, comprehensive utilization efficiency) and presents it through curves, bar charts, and pie charts.

This facilitates more rational and scientific management of the wastewater treatment system and provides efficient and accurate information support for optimization and upgrades. -

Intelligent Alarming: The system incorporates intelligent alarm algorithms to provide accurate, timely, and scientific early warning and alarm reminders, such as water level exceedance alarms and current exceedance warnings.

Alerts can be sent via WeChat, SMS, email, etc., reducing management difficulty and enhancing timeliness to ensure prompt handling of issues. -

Customizable Configuration Flow: To provide users with a clearer understanding of the operational status of the entire wastewater treatment system, the system allows customization of the configuration flow. It can authentically reflect the operational flow (animated graphics), equipment positions, and operational status in simulated scenarios, and support multi-mode operations such as starting and stopping.

-

Video Integration: Given the complex and widely distributed environment of wastewater treatment sites, the system supports video integration, enabling the viewing of on-site conditions through monitoring pages. This reduces the need for on-site inspections, achieving remote online unmanned operation and saving manpower and material resources.

-

Go Top

Go Top