-

What Are the Functions of a PLC Data Acquisition and Remote Monitoring System for Overhead Crane Equipment?

2025-08-27 17:59:20

An overhead crane, also known as a bridge crane, is a device used for lifting and transporting materials.

It primarily consists of a bridge frame, wheels, lifting mechanism, electrical system, hydraulic system, and control system. Operating in the air to transport materials within workshops, warehouses, and stockyards, it enhances resource turnover efficiency by avoiding obstacles from ground-level equipment.Overhead cranes equipped with PLC control systems enable automated material transportation, providing precise control over lifting height, operating speed, and motors to ensure efficient and safe material handling.

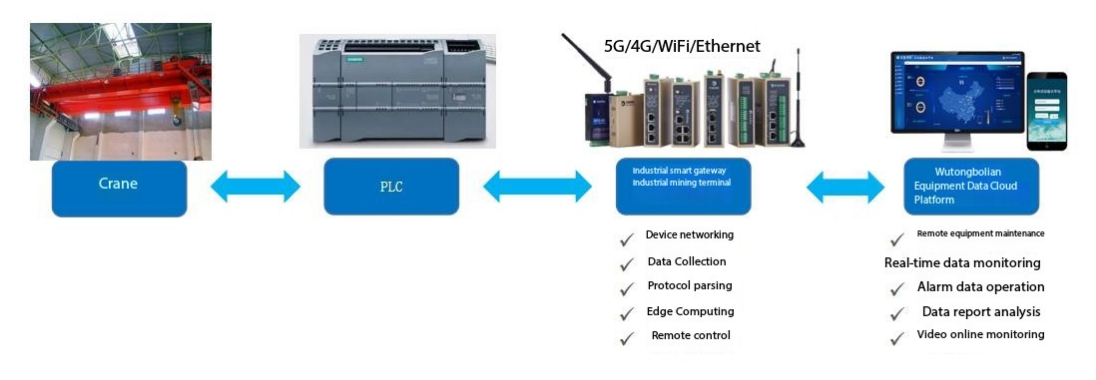

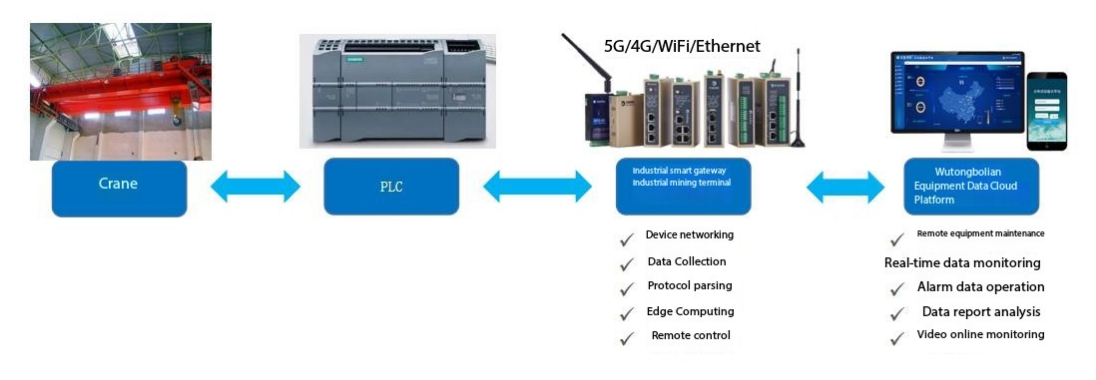

By collecting and monitoring data such as temperature, vibration, current, and voltage in real-time, the system can assess equipment status, trigger alarms, and facilitate management and maintenance, thereby strengthening on-site management levels and work efficiency.Wutongbolian introduces a PLC data acquisition and remote monitoring system for overhead crane equipment, primarily composed of a data acquisition gateway and a remote monitoring platform.

The data acquisition gateway collects real-time operational data from the overhead crane equipment and transmits it via communication methods such as 5G/4G/WIFI/Ethernet. The remote monitoring platform provides real-time monitoring and management of remote devices, promptly reporting equipment faults and offering visual remote management tools.

System Functionalities

-

PLC Data Acquisition: The system can perform real-time acquisition and transmission of PLC data from overhead crane equipment, including control instructions, operational status (on/off), and operating parameters (e.g., lifting capacity, lifting height, operating speed).

-

Remote Monitoring: The system enables remote monitoring and control of the PLC data acquisition process for overhead crane equipment, including real-time PLC data monitoring, remote control, and fault diagnosis, accessible via mobile and computer terminals.

-

Data Analysis: The system can analyze and statistically process PLC data from overhead crane equipment, including operational data, work efficiency, and energy consumption indicators, providing data support for equipment management and optimization.

-

Remote Control: The system allows for remote control and operation of overhead crane equipment, including starting, stopping, adjusting, and fault handling, to avoid potential accidents from on-site operations.

-

Remote Maintenance: The system facilitates remote programming, debugging, and program uploading/downloading of PLCs, improving maintenance work efficiency and reducing travel costs.

-

Go Top

Go Top