-

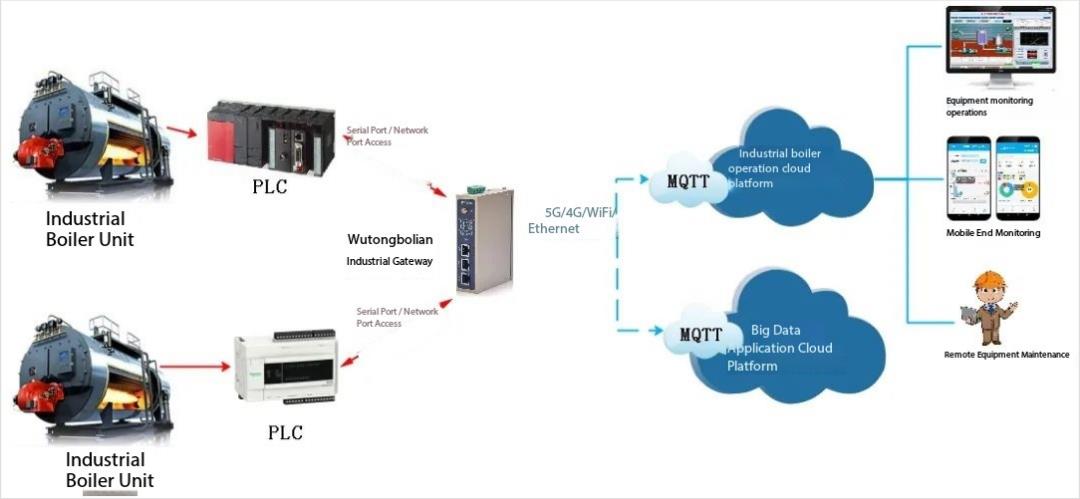

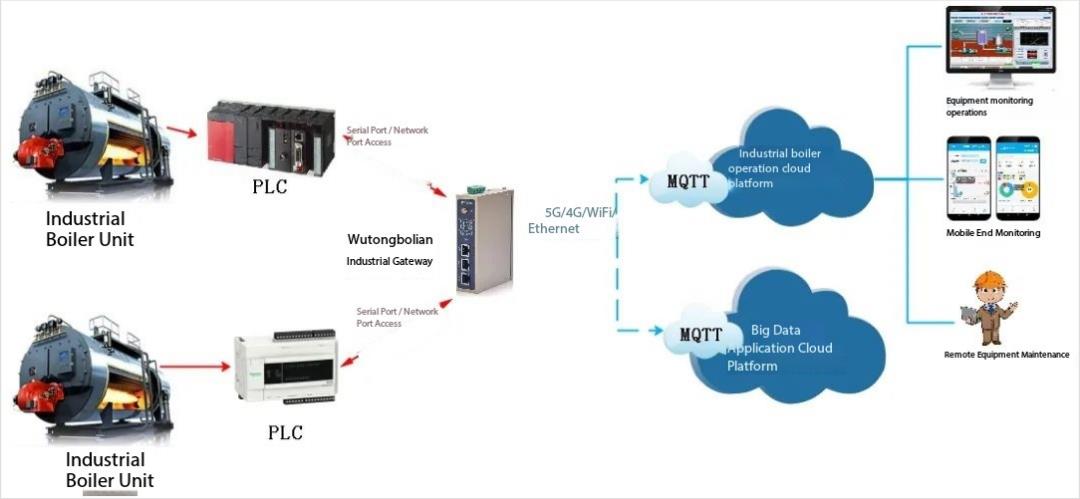

Energy-Saving Industrial Boiler Data Acquisition and Remote Monitoring Solution

2025-08-27 17:31:12

Due to the production characteristics of industrial boilers being "highly polluting, energy-intensive, and water-consuming," the boiler industry often incurs significant energy consumption costs, playing a crucial role in energy utilization and environmental pollution. Therefore, the country strongly supports the promotion of energy-saving and environmental protection industries to achieve efficient energy conservation, advanced environmental protection, and comprehensive resource utilization. Energy-saving industrial boilers represent a new type of equipment in the energy-saving and environmental protection sector.

Energy-saving industrial boilers offer advantages such as high thermal energy conversion efficiency, low coal demand, and versatile functionality, effectively reducing energy consumption costs and environmental pollution.

Similar to traditional boilers, they feature highly automated PLC control systems for automatic boiler production control. In response, Wutongbolian provides a PLC data acquisition and remote monitoring solution based on industrial intelligent gateways to further enhance intelligent energy management and optimization for boilers, primarily addressing the following issues:

-

Energy Consumption Data Acquisition: The gateway can interface with PLCs, water and electricity meters, sensors, and other devices to collect real-time data on electricity and water usage, temperature, humidity, flow rate, pressure, and equipment switch status, enabling energy consumption and equipment monitoring. Data reports and curve graphs are provided for visualization.

-

Energy Consumption Overlimit Alarms: The gateway automates energy consumption data collection and triggers alarms when abnormal overlimit data is detected, notifying managers via WeChat, SMS, email, and other means to promptly inspect and manage faulty equipment.

-

Remote Control and Maintenance: By analyzing data on temperature, pressure, and water level, equipment fault analysis and maintenance needs can be determined. The boiler, fans, and motors can be remotely controlled for start/stop and operational modes. PLC remote programming, debugging, and program uploading and downloading operations are also supported.

-

Energy Consumption Optimization Management: Leveraging big data analysis and intelligent algorithms, boiler energy consumption analysis models can be constructed to assess and analyze energy consumption levels, structures, abnormal energy consumption information, and pollution source data, driving decision-making management upgrades to reduce energy consumption and environmental pollution.

-

Energy Application Expansion: The gateway can also interface with energy storage systems, sewage treatment systems, and other equipment to achieve real-time data sharing and intelligent alarms, effectively reducing energy consumption, balancing energy source structures, and enhancing environmental protection benefits while further decreasing energy consumption costs.

-

Go Top

Go Top