-

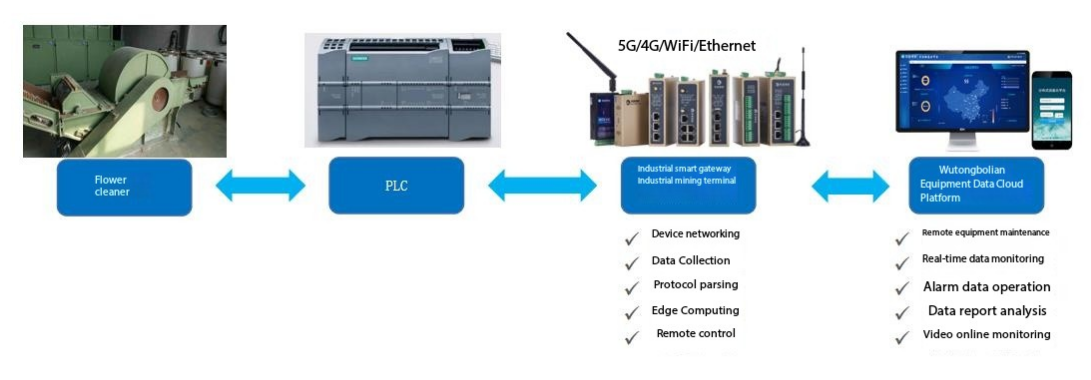

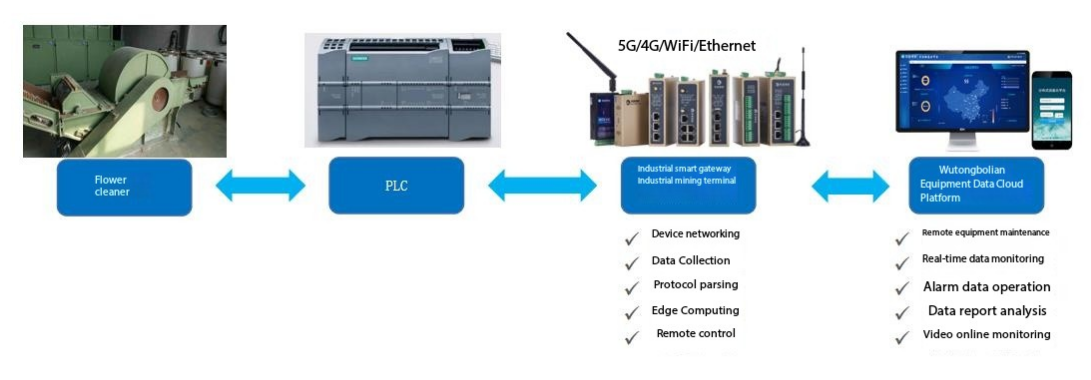

How to Achieve Data Acquisition and Remote Monitoring for PLCs in Textile Mill's Cotton Cleaning Machines

2025-08-27 17:24:34

Cotton cleaning machines are pre-spinning equipment for the pretreatment of cotton fiber raw materials, primarily used for separating, fibrillating, splitting, and removing impurities from cotton fibers, which significantly impact product quality.

PLC-controlled cotton cleaning machines enable automated production control, offering advantages such as high output, high efficiency, ease of operation, and low labor costs, thereby better supporting the expansion of production and operation scales.Although automation transformations in textile mills have gradually become widespread, issues such as data silos in equipment and traditional production and management methods have not been simultaneously resolved and updated, greatly constraining the development of digital management in textile enterprises.

In response, Wutongbolian provides an industrial intelligent gateway as a core device to accomplish real-time acquisition and edge processing of vast amounts of multi-source heterogeneous data, aiding in the enhancement of production efficiency and management effectiveness.The industrial intelligent gateway connects to the PLC of the cotton cleaning machine via serial ports and network interfaces for data acquisition and real-time communication.

It interfaces upwards with configuration monitoring software, MES systems, or energy consumption analysis platforms to achieve equipment status monitoring and fault alarms, visual monitoring and out-of-limit alarms for process and equipment parameters, and display of important parameter setpoints. This, in turn, facilitates production control, equipment maintenance, and energy consumption optimization, enabling intelligent, networked, and efficient production management.

System Functionalities

-

Real-time Monitoring: Continuously monitors the operational status and data of the cotton cleaning machine, including temperature, humidity, pressure, current, and voltage.

-

Data Analysis and Processing: Analyzes and processes the operational data of the cotton cleaning machine, detecting abnormal data and fault information, and automatically triggering alarms.

-

Feedback and Remote Control: Feeds back the analysis results to the control program of the cotton cleaning machine, enabling remote control and parameter adjustments.

-

Remote Monitoring and Management: Monitors the operational status and data of the cotton cleaning machine through intelligent terminals, facilitating remote monitoring and management.

-

Historical Data Recording and Storage: Records and stores the operational data of the cotton cleaning machine for subsequent data analysis and traceability.

-

Automated Control and Intelligent Management: Enables automated control and intelligent management of the cotton cleaning machine, enhancing production efficiency and quality.

-

PLC Remote Programming and Maintenance: Facilitates remote programming, maintenance, and program uploading and downloading for PLCs, improving maintenance efficiency and reducing costs and risks.

-

Go Top

Go Top