-

The Crucial Role of Remote IO Data Acquisition in Industrial Automation Systems

2025-08-28 17:28:00

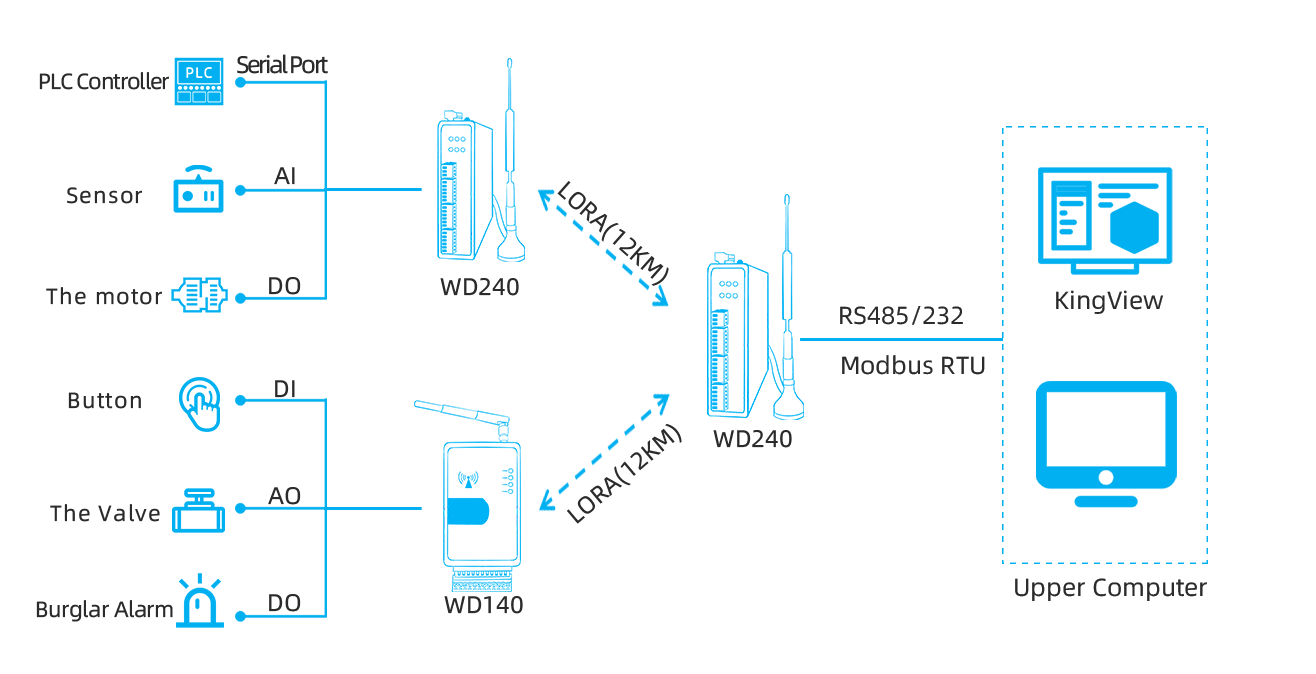

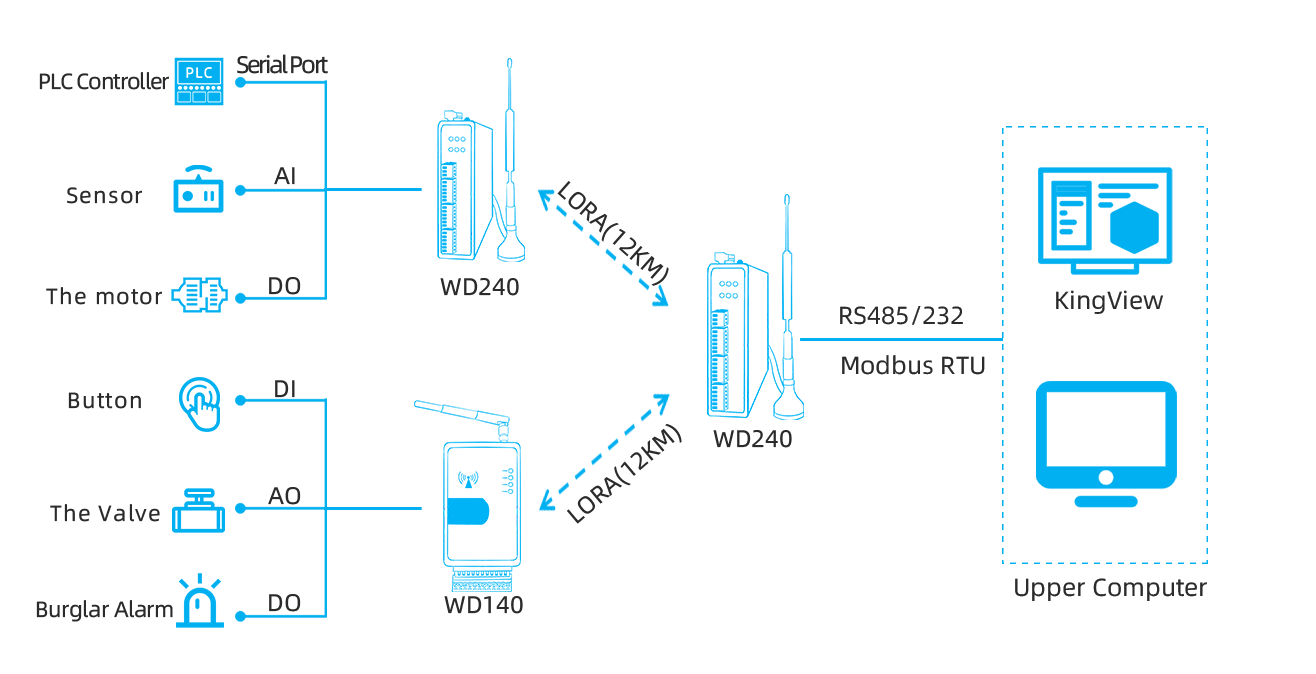

This technology enables data communication between remote devices and monitoring centers over long-distance communication ranges without extensive construction and wiring, allowing personnel to work remotely from the equipment. This enhances flexibility and scalability, offering numerous benefits and advantages, such as connecting sensors, PLCs, and other devices to a cloud platform for remote monitoring, management, and maintenance.

Principle of Remote IO Data Acquisition

The core of remote IO data acquisition lies in the IO data acquisition terminal, which facilitates real-time communication between industrial equipment and the monitoring center.

Essentially, it decodes the output signals from devices into a format that the platform can read and respond to; similarly, it converts input signals from other devices into a format understandable by field devices, enabling data communication and remote control. Note that PLCs, sensors, and other devices typically have specific protocols, which the IO data acquisition terminal must support.Why Remote IO Data Acquisition is Necessary

Remote IO data acquisition overcomes spatial limitations.

In traditional IO systems, devices must be directly connected to field equipment, posing challenges for distributed, large-scale applications. Remote IO data acquisition allows deployment of IO data acquisition terminals in different regions, utilizing local computing resources to balance loads. It also simplifies adding or removing devices and enables unified configuration, quickly integrating with existing networks to reduce costs and enhance efficiency.

Components of a Remote IO Data Acquisition System

A remote IO data acquisition system comprises multiple software and hardware components to ensure effective communication between the monitoring center and field devices.

Typically, it includes IO data acquisition terminals, field sensors or programmable logic controllers (PLCs), communication networks, and a monitoring platform or upper computer.-

IO Data Acquisition Terminal: This acts as a bridge between field devices and the monitoring platform.

It enables wireless internet access (e.g., 4G, WIFI) for field devices and provides reliable means for remote monitoring, management, and control. -

Field Sensors or PLCs: These generate various IO signal data, such as temperature, humidity, pressure, and liquid level, which can be collected and processed by the IO data acquisition terminal. Conversely, the terminal can receive instructions to control field devices, such as starting or stopping motors and opening or closing valves.

-

Communication Network: This serves as the carrier for all data exchanges and can include wireless networks (e.g., 4G, WIFI) and wired Ethernet networks.

-

Monitoring Platform: This acts as the brain of the system, receiving and processing IO data to provide functionalities such as visual charts, data reports, and trend analysis. It also feeds back control commands to field devices to meet intelligent and remote work requirements.

-

Go Top

Go Top