-

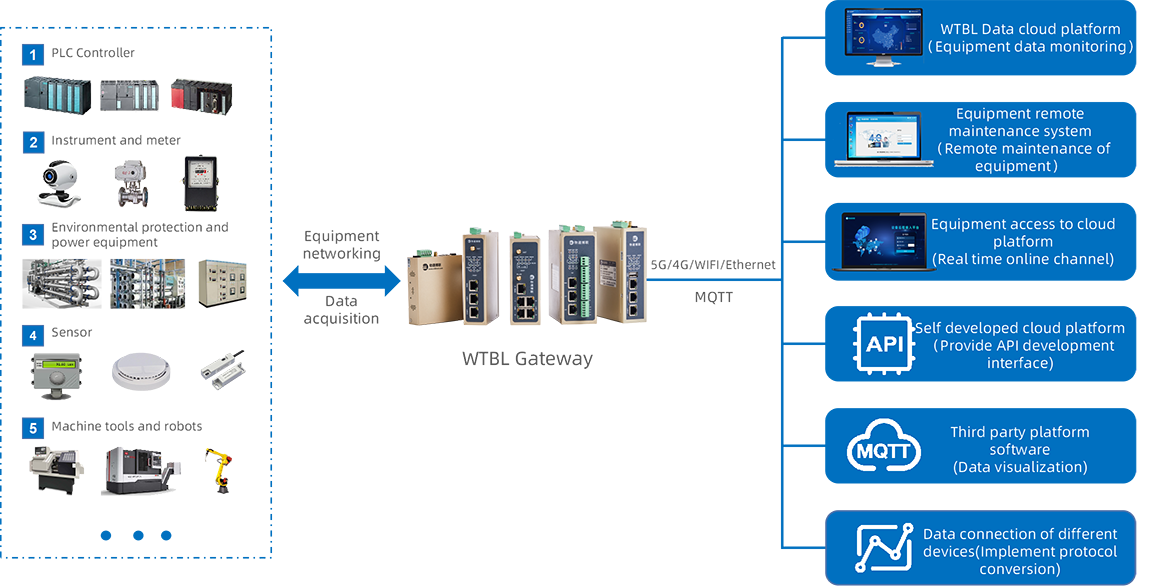

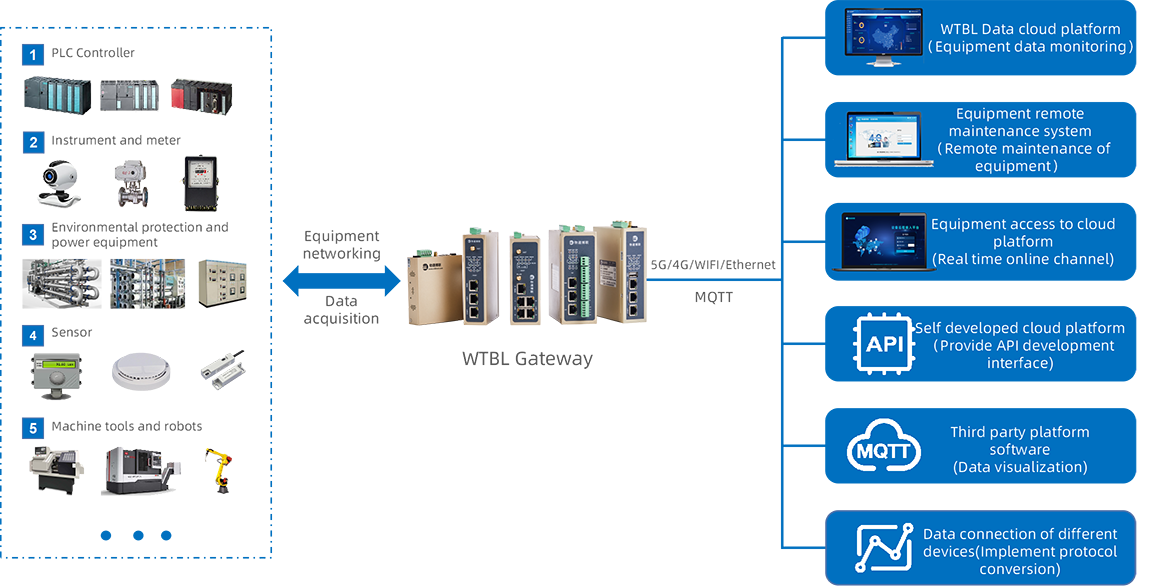

System Architecture of Industrial Smart Gateways in the Industrial Internet of Things (IIoT)

2025-08-28 17:24:06

In the system architecture of the Industrial Internet of Things (IIoT), an intermediary device is required to bridge the gap between industrial equipment and cloud platforms operating on two distinct network systems. This device is known as the "Industrial Smart Gateway."

Wutongbolian's Industrial Smart Gateways are capable of connecting to PLCs, sensors, instrumentation, CNC machine tools, industrial robots, and more.

They collect data from these devices and communicate it via 5G, 4G, WIFI, Ethernet, and other means. The data is then transmitted to remote cloud servers in standard or specific JSON formats using protocols such as MQTT, HTTP, and TCP.

System Architectures of Industrial Smart Gateways in IIoT

- Device/Sensor - PLC - Gateway - Cloud

This system architecture is one of the most prent in current IIoT models.

The gateway serves as a crucial device for protocol parsing and data collection, acting as a bridge between the PLC and the cloud. This setup facilitates seamless PLC data collection, remote PLC control, remote PLC programming and debugging, as well as remote PLC program uploading and downloading. Consequently, remote monitoring and management are achieved over the network, significantly enhancing work efficiency and management levels.- Sensor - IO Module - Gateway - Cloud

This model offers a convenient and flexible solution for monitoring and alarming equipment that is outdated, lacks modification, or has no control system.

In this scenario, the IO terminal functions as a central node for multiple sensors at the bottom level. The gateway performs further computations and processing on the data, enabling equipment status monitoring within a limited cost framework. This approach better supports production management and also allows for simple local IO control.- Sensor - Gateway - Cloud

Devices such as sensors and water/electricity meters can also be directly connected to the gateway for data collection and real-time communication. In this case, the gateway needs to possess IO data acquisition capabilities to directly monitor parameters like temperature, humidity, pressure, flow, and vibration. This model primarily enables distributed, multi-site equipment data acquisition management, with the gateway providing networking, internet access, and data communication functionalities.

Go Top

Go Top