-

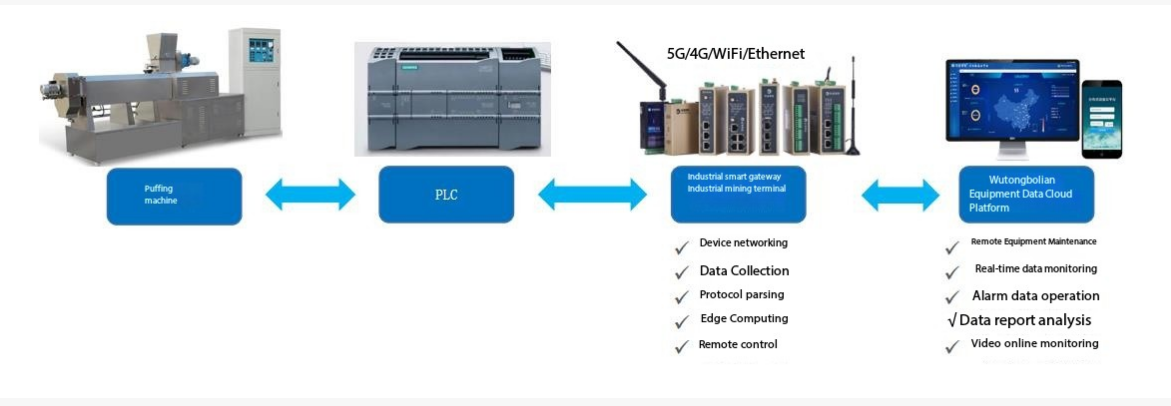

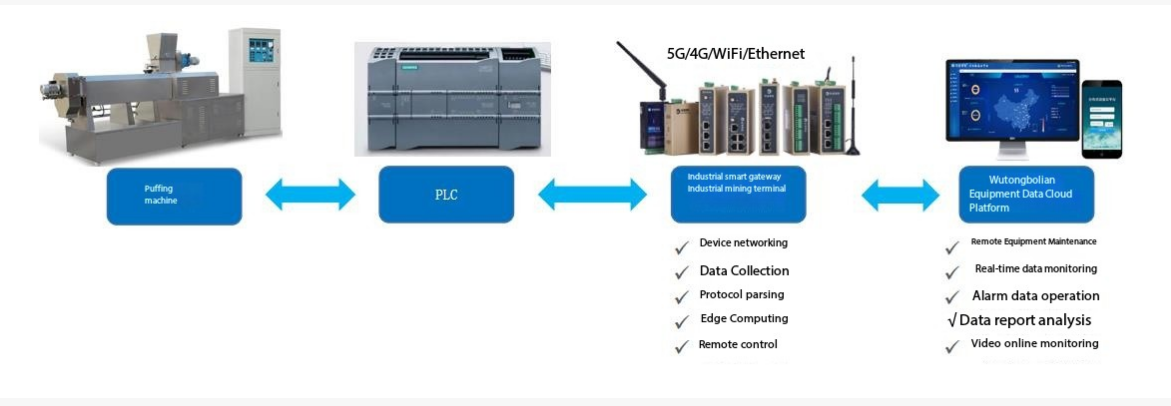

Puffing Machine Data Acquisition and Remote Monitoring IoT Solution

2025-08-27 17:40:30

A puffing machine is a piece of equipment that utilizes high-pressure and high-temperature technology to puff raw materials, commonly used in fields such as food, feed, and chemicals.

Its primary working principle involves instantly heating and expanding raw materials under high pressure and temperature, increasing their volume and density while altering their internal tissue structure to improve taste, nutritional value, and texture.Automated production of puffing machines can be achieved through PLC control, where data such as temperature, humidity, pressure, voltage, and current are crucial for production stability.

Any abnormalities in these key parameters can lead to equipment shutdowns, production halts, and material losses, causing significant financial harm to customers. Therefore, many manufacturers are enhancing the remote monitoring and maintenance capabilities of their puffing machines while selling them, aiming to achieve rapid fault handling and provide excellent after-sales service.By connecting the PLC to the Wutongbolian industrial intelligent gateway, the gateway can real-time collect data on temperature, humidity, pressure, voltage, and current, and upload it to cloud platforms or upper computer systems via 5G/4G/WIFI/Ethernet.

This enables features such as automatic data over-limit alarms, remote equipment control and maintenance, and production efficiency and output analysis, assisting manufacturers in achieving refined equipment management and strengthening regulatory and maintenance capabilities.

Functional Characteristics:

-

Real-time Monitoring: Through PLC data acquisition and real-time communication, the working status of the puffing machine is continuously monitored, allowing for timely detection of faults and alerts via WeChat, SMS, or email.

-

Remote Monitoring: Remote monitoring of puffing machine data is achieved through mobile and computer terminals, enabling queries on equipment location, status, and production efficiency, facilitating remote management and control by managers.

-

Data Analysis: The collected data is analyzed and processed to provide data support for production management, energy consumption optimization, and efficiency improvement, contributing to enhanced production efficiency and product quality.

-

Enhanced Protection: The gateway ensures data security and integrity through features such as multi-network redundancy,断点续传 (breakpoint continuation), watchdog, and firewalls, better meeting the demands of industrial data security.

-

Cost Reduction and Efficiency Enhancement: Remote equipment start/stop control, remote PLC debugging, and remote PLC program uploading and downloading reduce personnel travel costs, improve work efficiency, and prevent accident escalation and increased losses.

-

Go Top

Go Top