-

Industrial IoT Data Acquisition: From Modbus to MQTT

2025-08-25 17:41:03 The Modbus protocol is a serial communication protocol used to connect industrial automation equipment. It enables data exchange and transmission of control commands between devices, allowing various devices such as sensors, motors, and PLCs (Programmable Logic Controllers) to work in coordination with each other. In contrast, the MQTT protocol is a lightweight message transmission protocol based on the publish/subscribe model. It supports large-scale data communication, well accommodates distributed systems and cloud computing platforms, and is one of the universal protocols in the current industrial Internet of Things (IIoT).

The Modbus protocol is a serial communication protocol used to connect industrial automation equipment. It enables data exchange and transmission of control commands between devices, allowing various devices such as sensors, motors, and PLCs (Programmable Logic Controllers) to work in coordination with each other. In contrast, the MQTT protocol is a lightweight message transmission protocol based on the publish/subscribe model. It supports large-scale data communication, well accommodates distributed systems and cloud computing platforms, and is one of the universal protocols in the current industrial Internet of Things (IIoT).

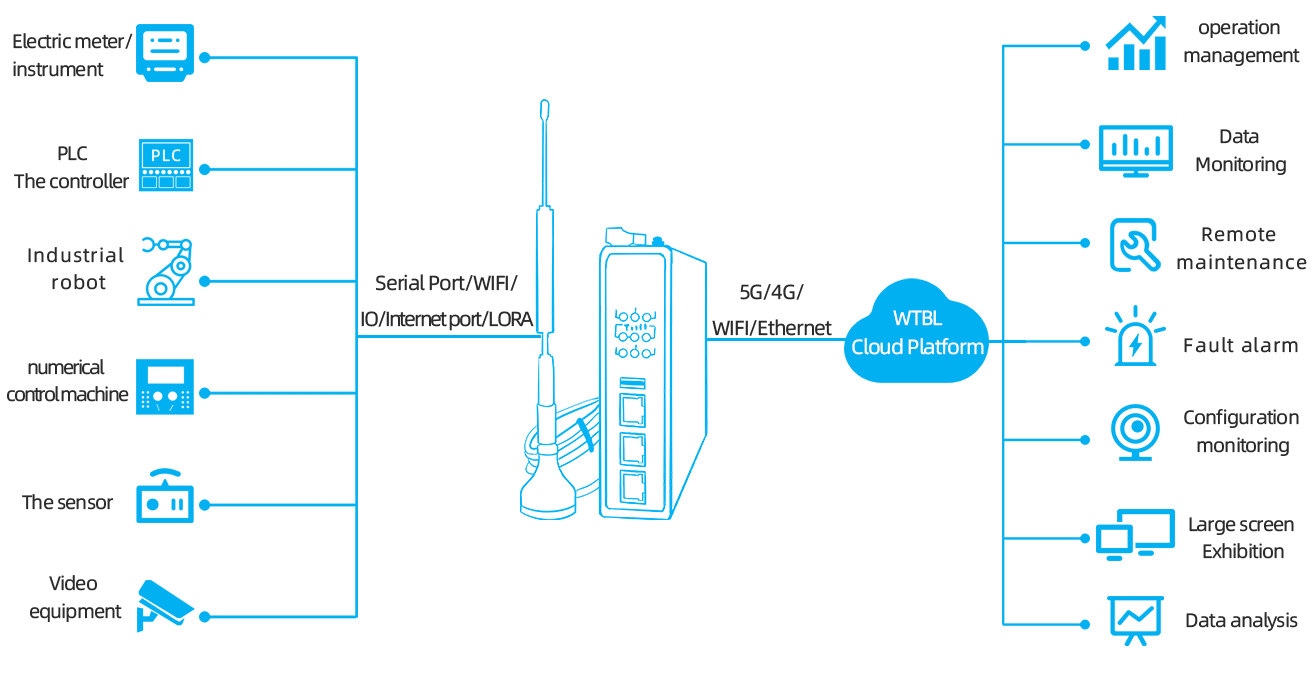

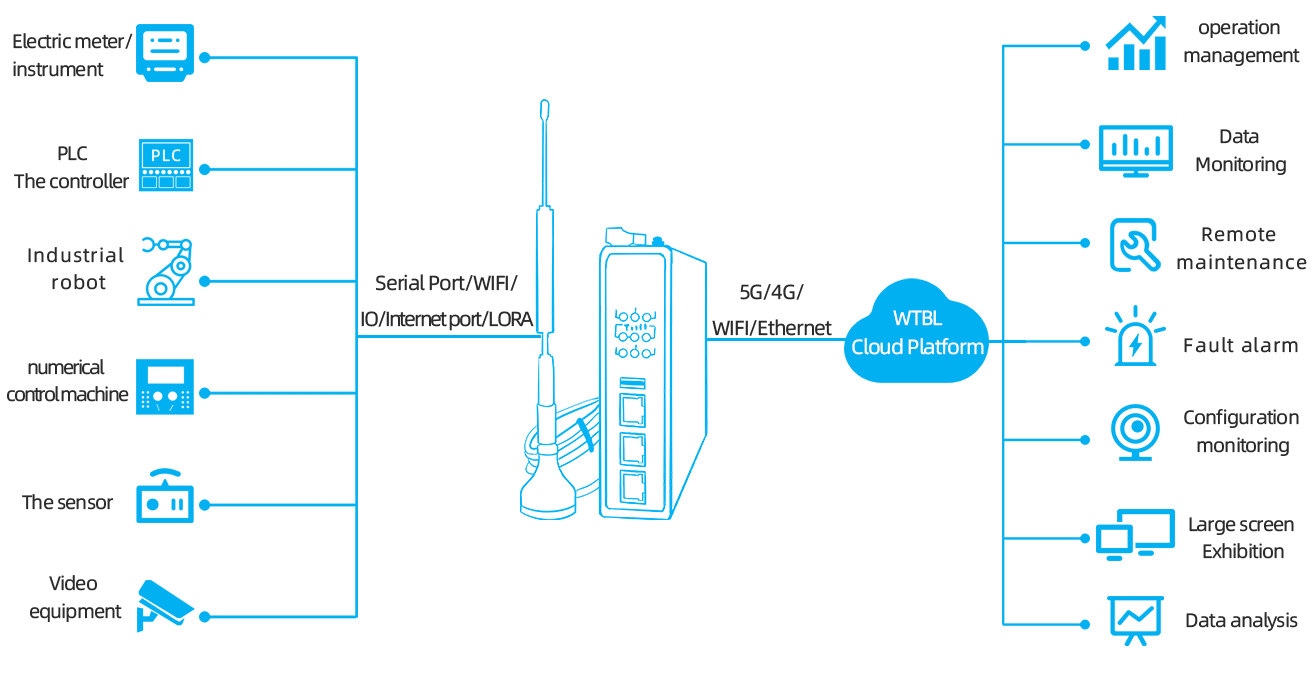

As the concept of the industrial Internet of Things gains increasing popularity, the demands for automation, intelligence, and data-driven operations in the manufacturing industry are also rising. A growing number of Modbus devices need to be connected to MQTT-based IoT platforms. In response to this need, Wutong Bolian provides an industrial intelligent gateway solution for converting Modbus to MQTT.

Modbus devices are connected to Wutong Bolian's industrial intelligent gateway. The gateway collects data from PLCs or Modbus devices, performs edge computing, standardizes the data, converts it to the MQTT protocol, and then connects it to the MQTT cloud platform. At this point, the industrial intelligent gateway fulfills the functions of Modbus-to-MQTT conversion and data acquisition & communication, supporting internet access methods such as 5G, 4G, WIFI, and Ethernet. It aims to solve the problem of difficult unified access to data from a wide variety of devices and provide data support for smart manufacturing.

Wutong Bolian's industrial intelligent gateway is equipped with local computing, storage, and processing capabilities. In industrial applications, it typically acts as a Modbus master: it collects data from Modbus devices locally, then processes and stores the data on-site. After protocol conversion, the data is proactively uploaded to the cloud platform via the MQTT protocol, achieving second-level data reporting.

Furthermore, the gateway supports functions such as remote configuration, remote deployment, and status query & monitoring. These features provide convenient means for device debugging and program upload/download in remote industrial sites, effectively supporting device management and maintenance work while improving work efficiency and management standards.

Go Top

Go Top