-

How to Achieve Remote Programming, Debugging, and Remote Program Uploading/Downloading for Beckhoff PLCs

2025-08-21 17:48:01

Beckhoff PLCs are common automated control devices in industrial production, and sometimes their programs require debugging and modification.

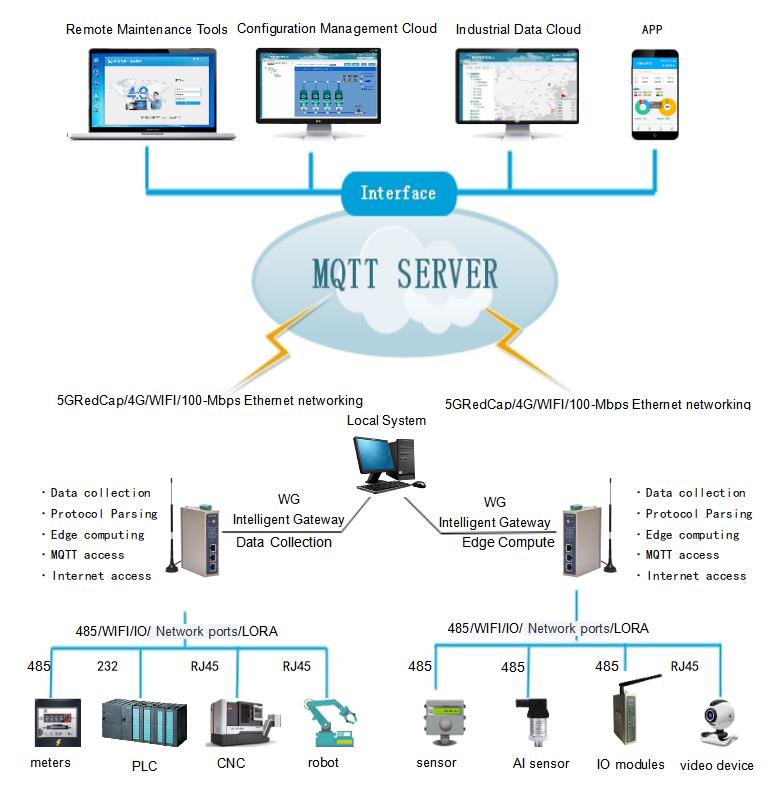

Opting to send engineers on-site for such tasks can be costly, involving additional expenses for transportation, accommodation, and meals. In such cases, adopting a solution for remote programming, debugging, and remote program uploading/downloading for PLCs proves to be more cost-effective, offering efficient work processes and effectively reducing operation and maintenance costs.This solution is implemented through industrial intelligent gateways provided by Wutongbolian (a hypothetical or generic name for a technology provider). These gateways offer protocol parsing and device networking capabilities, capable of parsing PLC protocols from Beckhoff, Siemens, Mitsubishi, Omron, Delta, and other manufacturers, as well as establishing communication networks via 5G/4G/WIFI/Ethernet.

They can collect data from PLC devices, obtain device status and operational parameters, and upload this information to a device management cloud platform in real-time for monitoring device status. Simultaneously, they provide visualized data displays and user-friendly interactive operation interfaces, allowing staff to view data reports and perform intelligent analyses on their mobile phones or computers at any time, thereby facilitating scientific and rational decision-making.

Users can communicate in real-time with remote PLCs through the gateway, modify PLC parameters, issue control commands, and achieve remote start/stop of devices.

When receiving device fault alarm notifications, engineers can establish secure and reliable remote maintenance channels via the device maintenance express line to perform operations such as remote program uploading/downloading and remote programming debugging, enabling efficient and low-cost maintenance work.Through PLC remote maintenance, enterprises reduce personnel travel and expenses while providing customers with more timely and efficient maintenance services, thereby enhancing their corporate image and reputation. Additionally, based on data management and analysis, predictive maintenance of devices can be achieved, offering customers more personalized and humanized services.

Go Top

Go Top