-

Industrial IoT Connects Smart Factories for Efficient Data Acquisition and Analysis

2025-08-21 17:41:35

The data acquisition work of Industrial IoT (IIoT) is at the core of digital transformation in smart factories, providing continuous and reliable data to further solidify a company's digital transformation efforts.

Generally, protocol parsing is required before data acquisition can take place.Currently, for production automation, process automation, or unmanned factories across various industries, data acquisition is an inevitable requirement.

However, depending on the industry, enterprise type, the enterprise's own digital knowledge reserves, and its stage of digitalization, the focus and priority of data acquisition construction may vary, leading to different needs.

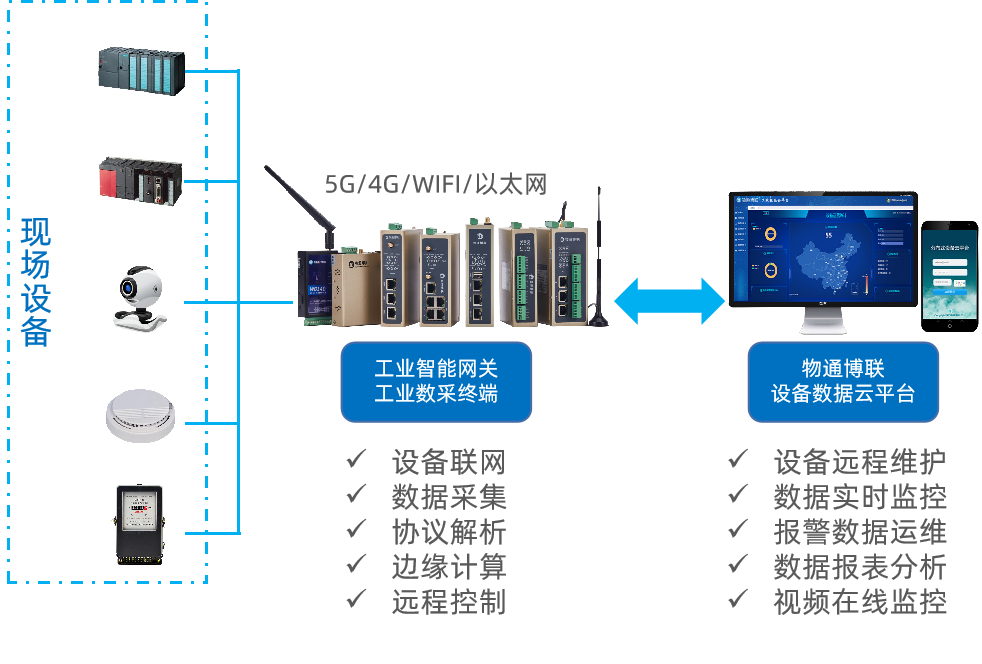

Based on the diverse needs of smart factories, Wutong Bolian offers efficient and reliable Industrial IoT solutions.

By connecting various devices in smart factories through industrial smart gateways, it performs protocol parsing and data acquisition, providing reliable management means for data analysis. This helps stabilize production, increase capacity, reduce abnormal equipment downtime, standardize operations and maintenance, and improve energy utilization efficiency.-

Device Data Visualization: The gateway can parse and acquire data from PLC devices, enabling visual monitoring of device status and process parameters.

It provides an overview of device maps and data dashboards, allowing real-time viewing of equipment working information and alarm information within the factory. This facilitates hierarchical and classified management, enhancing equipment management levels and resource utilization efficiency. -

Energy Data Visualization: By acquiring data from energy meters for water, electricity, gas, and heat, energy management can be realized across different workshops, devices, and time periods on the platform.

This enables the identification of optimization opportunities and the implementation of measures for energy optimization and consumption improvement, providing data support. -

Operations and Maintenance Management Visualization: On the platform, all device alarm records, operations and maintenance information, etc., can be queried and managed at any time. This includes viewing alarm information, operations and maintenance logs, and customer feedback, effectively improving enterprise equipment after-sales service, establishing an operations and maintenance knowledge base, and providing reliable optimization directions for the enterprise.

-

Go Top

Go Top